The die head of the blow molding machines , which is also known as the clegi, is an important part of the Bloemolding extrusion machine. Blown plastic machine as one of the main equipment for producing plastic products consists of extruder, die head, and blowing system. The die head is a vertical piece at the end of the extruder cylinder.

Two types of die heads are currently in use, one is the continuous die head and the other is the storage die head.

The role of the die head in the blow molding machines

Die head is the main part of the extrusion of plastic parts. It causes the molten plastic from the extruder to change from a spiral to a linear motion and gradually creates the necessary molding pressure to ensure the compression of the plastic parts to achieve a cutting edge. and produce continuous forms that are similar in shape.

Usually, extruded plastic parts include bottles, gallons, and other blow molding plastic products.

Application of die head

Although the plastic part extruded from the mold has a predetermined shape, because the temperature of the part is relatively high, it deforms due to its own weight, so it is necessary to use the machine to cool and shape the part. measurement to be used. , so that the quality of the appropriate surface for the products is obtained. A chiller cooling method is usually used to stabilize the pre-determined shape of the plastic extruded from the mold and then complete it to stabilize the quality of the final product.

Types of die head of blow molding machines

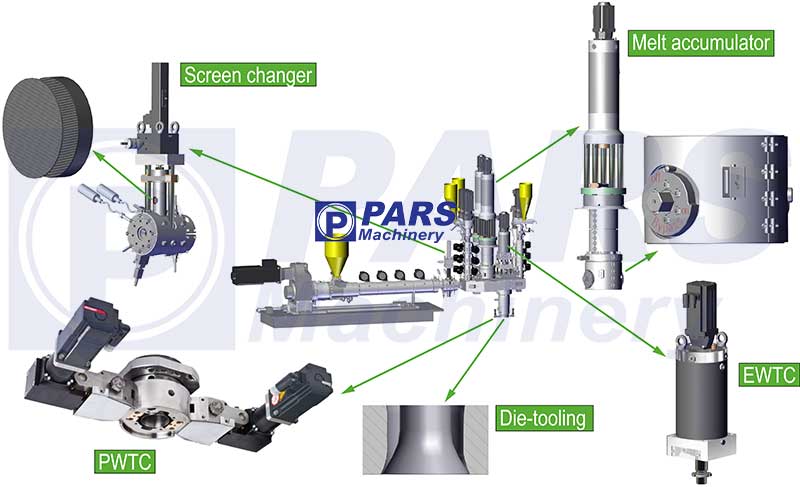

The die head of the Bloemolding extrusion machine, from which a tube of molten resin comes out, is called a die head. There are different classifications of blow molding die heads that are commonly used. Based on the processing method, the die head can be a continuous die head or an accumulator die head. Based on the number of parisons, it can be a single parison or a die head with multiple parisons. Then it is divided based on the number of layers – single layer, multi layer, etc.

Continuous die head

In this type of die head, the molten resin is continuously discharged from the extruder in the form of a parison or a tube. Parison continuous die heads can have central or side feeding, depending on the molten resin entering from the extruder to the die head.

Accumulator die head

Here, the molten resin of the extruder is stored inside the accumulator die head and is ejected by external force at the start of each molding cycle. The volume of material that can be stored usually depends on the size of the head (such as 5 liters, 20 liters, etc.). There are different types of accumulators.

The oldest type of die head is with an external accumulator where the accumulator chamber is outside the die head. In this type, higher power is needed to press the parison and the quality of parison is not good.

Another type is die head. The quality of parison in this model is much better compared to the external accumulator and the power consumption is low. Early models were such that the first molten resin entered remained for a longer period of time, leading to degradation of the resin. Another type was then developed in which the primary resins remained for a shorter period of time, resulting in less degradation of the resin. This process gives the best quality parison.

Another type of accumulator die head is the screw type where the accumulator housing is along the extruder like injection machines. This type has the least degradation of molten resin and is suitable for sensitive materials such as PC and so on.

Die head with multiple Parisons

In this model, several parisons are created simultaneously in a production cycle, which leads to higher productivity. While the single parison type is the most common, multi parison die heads are common for smaller bottles and containers that require higher production capacity.

Multi-layer die head

In multi-layer heads, multiple extruders process different materials or similar materials with different colors and form concentric parisons to increase the properties of the final product.