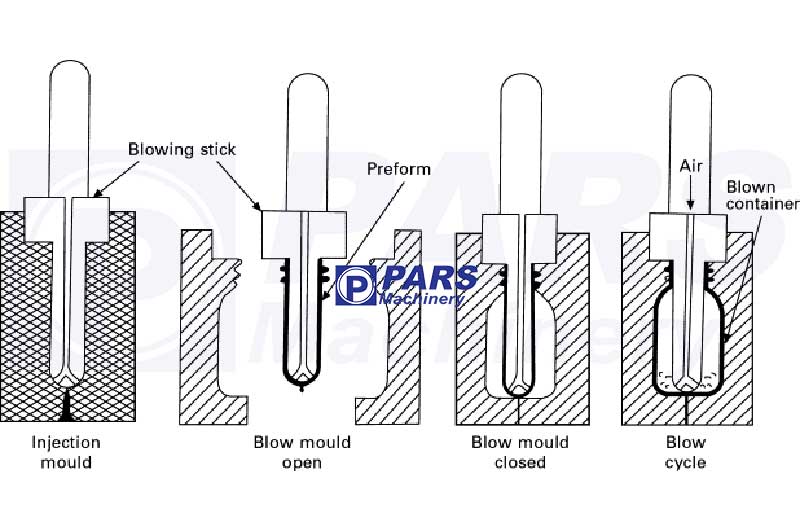

The Injection blow molding machine is used to produce large quantities of hollow products, e.g. Bottles, cans and many other containers in various industries such as pharmaceutical and health industries, cosmetic industries, food industries and this process has three stages – injection, blowing and separation.

How the Injection blow molding machine works

Injection – Molten plastic is injected into a preheated hollow mold that forms the external shape. The plastic wraps around a mandrel (core rod) that forms the inner shape. This performance is produced with a fully formed neck from a bottle or glass.

Blowing – The mold is opened and the core bar is closed with a cold blow mold. The core rod opens and allows compressed air to blow it to its final shape.

Stripping – After cooling the mold is opened and the manufactured product is separated from the core bar. As with plastic injection molding machines, blow molds can have multiple holes.

Raw materials used in Injection blow molding machine

Many materials and polymer materials can be used to produce products with an Injection blow molding machine. Materials used for Injection blow molding machine include polyethylene (high density, low density and linear low density), polypropylene, polyethylene terephthalate (PET) and PVC.

The difference between blow molding and Injection blow molding machine

The main difference between an injection molding machine and a blow molding machine is in the type of products they create. IBM is typically used to form smaller parts, which can include medical parts, kitchen parts, and other solid components. Meanwhile, EBM is used to make larger hollow parts such as bottles, gallons, cauldrons and other containers. Extrusion plastic can produce more complex shapes due to the way the product is formed. However, the Injection blow molding machine is able to produce a large volume of quality parts quickly and accurately.

Injection blow molding molds

For an Injection blow molding machine , there must be a very precise fit between the two halves of the mold to allow full control over the resin flow. Most of the work related to injection molding involves mold production. In EBM, there is a higher level of design flexibility between the two mold halves because each half forms its own wall shape.

Features of Injection blow molding machine

One-step molding keeps the final bottle shape cleaner. Suitable for cosmetics, pharmaceuticals, food industries and…

Energy saving Saves 50% to 70% electricity.

Automatic production without the need for a thrower

Production of seamless products

Stable performance and low noise.

The aluminum frame makes monitoring and maintenance easier and has a more modern look.

The touch screen with graphical interface makes it easy for the user to work.

Programmable for each injection and plasticization automatically

The actual values of time, speed and pressure of injection and plasticization can be monitored and controlled by the terminal.

Automatic failure detection and warning message display on the touch screen.

The injection mold and the injection blow mold can be controlled separately, so shorter cycle times with faster processing are possible.

Applications of Injection blow molding machine

The Injection blow molding machine can be used to create different types of parts. The parts produced by air injection process are generally plastic, hollow and single-walled. These types of products are used regularly and are available in different shapes and sizes. Some of these types of Injection blow molding machine products are:

Bottles of serum and all kinds of pharmaceutical products

Shampoo bottles

Plastic cans

Dairy storage bottles

Medical droppers

All kinds of cosmetic bottles

And many packaging applications in various industries.

Price and purchase of Injection blow molding machine

There are different types of Injection blow molding machine, each of which is suitable for the production of different products. Typically, smaller machines that produce smaller capacity products cost less than larger Injection blow molding machine. Also, one of the factors influencing the price of plastic injection machines is whether the machine is electric, pneumatic, or hydraulic.

All-electric Injection blow molding machine are suitable for medical environments and pharmaceutical industries due to the lack of pollution.

Dear friends, you can contact our technical experts to know the price of different Injection blow molding machine and also to get advice and expertise to choose the right mchine.